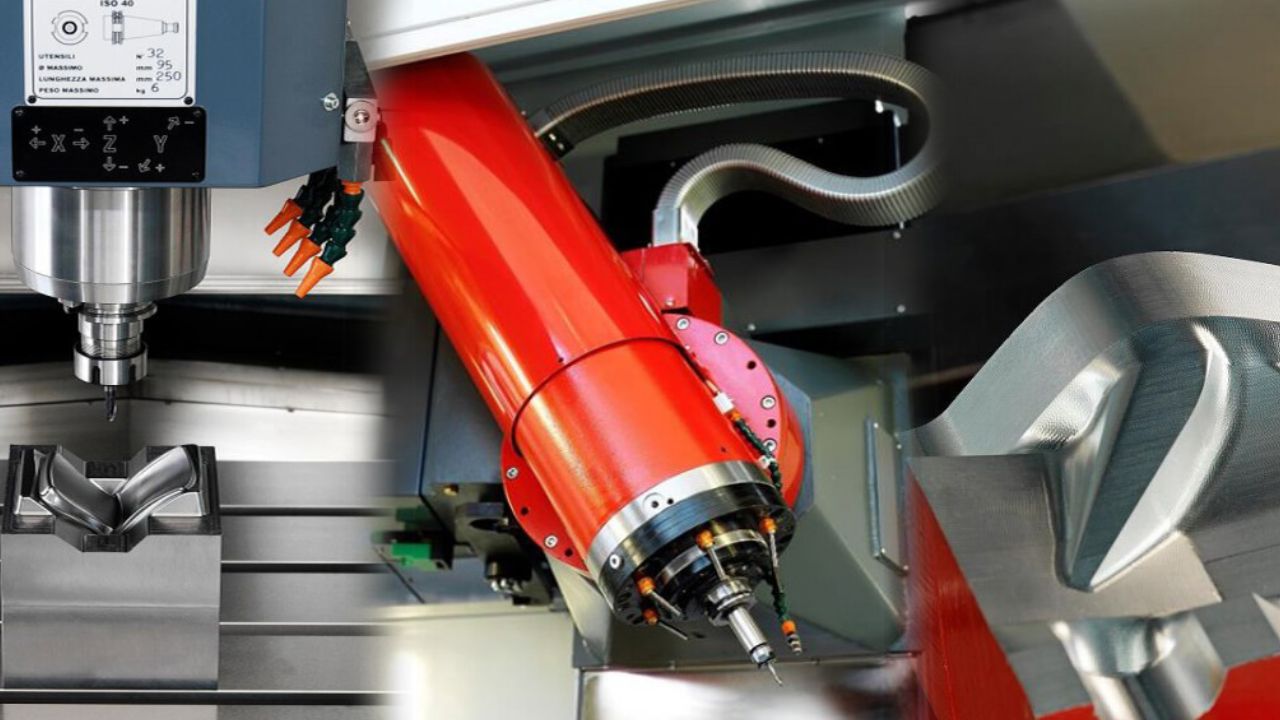

The engine of all contemporary industrial processes is the CNC machine. CNC machines are suitable for all applications, from high-volume manufacturing models to precise prototypes. For this reason, these machines have developed into a wide variety of models to meet the needs of specific applications.

Of the various forms, multi-axis CNC machines have emerged as the standard choice. They are able to produce items with extreme precision requirements or high levels of complexity. Owing to the advancements in technology many experts are frequently curious about the fundamentals of multi-axis CNC machines and whether they are practical for certain uses.

Multi-axis CNC machining is a sophisticated manufacturing process that involves the use of computer numerical control (CNC) machines capable of moving in multiple directions simultaneously. This capability allows for highly complex and intricate machining operations, enabling the production of intricate parts and components with precision and efficiency. You can click here to this link to get details about Multi-axis CNC machining.

Principles of Multi-axis CNC Machining

Multi-axis CNC machining expands on the fundamental principles of traditional CNC machining by introducing additional axes of movement. These additional axes, often labeled as A, B, and C, enable the cutting tool to approach the workpiece from various angles, providing greater flexibility and versatility in the manufacturing process.

In addition to these rotational axes, multi-axis CNC machines can incorporate linear movements along the traditional X, Y, and Z axes, resulting in simultaneous multi-axis motion. By combining these movements, the cutting tool can approach the workpiece from virtually any direction, enabling intricate cuts, angles, undercuts, and complex geometries.

A-Axis

The A-axis represents a rotational movement around the X-axis. It allows the workpiece or the cutting tool to rotate horizontally, enabling the machining of features on different faces of the workpiece without the need for repositioning.

B-Axis

The B-axis is a rotational movement around the Y-axis. It permits rotation vertically, allowing for machining operations on inclined or contoured surfaces.

C-Axis

The C-axis involves a rotational movement around the Z-axis. It allows the workpiece or tool to rotate perpendicular to the cutting plane, facilitating operations on cylindrical or circular features.

Positive Facts of Multi-axis CNC Machining

In this comprehensive discussion, we will explore some key facts of multi-axis CNC machining, shedding light on how this advanced technology revolutionizes the manufacturing landscape.

Precision and Accuracy

One of the primary advantages of multi-axis CNC machining is its exceptional precision and accuracy. By enabling simultaneous movement along multiple axes, these machines can create intricate and complex geometries with high tolerance levels. This precision is crucial in industries such as aerospace, automotive, and medical devices, where even the slightest deviation from specifications can lead to functional issues or product failure.

Increased Efficiency

Multi-axis CNC machines significantly enhance efficiency in the manufacturing process. Traditional machining methods often require repositioning the workpiece multiple times to access different angles, leading to longer production times. Multi-axis machines, on the other hand, can perform various operations in a single setup. This reduction in setup time translates to faster production, shorter lead times, and increased overall efficiency in the manufacturing workflow.

Complex Geometries and Intricate Parts

The versatility of multi-axis CNC machining allows for the production of highly complex geometries and intricate parts. Whether it's sculpted surfaces, undercuts, or features with varying angles, multi-axis machines can handle these challenging designs with ease. This capability is invaluable in industries that demand innovative and intricate components, such as the production of high-performance automotive parts and advanced medical devices.

Bottom Line

Multi-axis CNC machining, with its ability to move in multiple directions simultaneously, offers a multitude of benefits that make it a preferred choice in various industries. From increased precision to enhanced efficiency, the advantages of multi-axis CNC machining are significant and impactful. The precision offered by multi-axis CNC machining ensures that parts are manufactured accurately the first time.